- July 27, 2022

- MSA Safety

Plant managers, process engineers and others responsible for fire safety in hazardous petrochemical and other industries will find the compact, versatile FL500 UV/IR Flame Detector from MSA Safety offers them dependable fire protection in crowded plant environments with its fast-response sensor and wide field-of-view (FOV).

The FL500 UV/IR Flame Detector monitors for radiation emitted by a flame in both the ultraviolet (UV) and infrared (IR) spectral ranges. This combination UV/IR optical sensor provides the fastest response time and increased false alarm immunity against common plant sources of radiation, such as tanks and large pipes, for more reliable protection. Avoiding false alarms reduces process and plant down time, as well as increases employee confidence in safety systems should an actual incident occur.

A helpful FL500 Flame Detector Simulator is now available on the MSA web site, which colorfully illustrates the FOV protection afforded by this precision UV/IR sensing technology in a variety of fuel environments.

Simulator viewers can see and compare the flame sensor’s FOV for common fuel sources including butane, ethane, heptane, hydrogen, methane, methanol and propane.

The advanced FL500 optical flame detector is FM performance approved for all seven different fuel sources shown on the simulator. By combining a precision ultraviolet (UV) sensor for quick response with an infrared (IR) sensor that monitors flame-emitted radiation, the FL500 flame detector operates at faster speeds with unsurpassed false alarm immunity to provide the industry’s most reliable monitoring in its class.

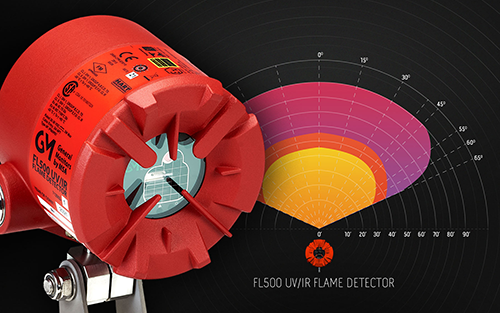

The FL500 detector offers a wide field of view up to 130° for optimum protection. It features three external LED indicators for local verification by technicians of normal operation, fault conditions, and alarms. On-board relays provide flexible detector status communications with automated plant safety and control systems via HART, Modbus, 4-20 mA sink or source communications.

Designed with continuous optical path monitoring (COPM) technology, the exceptionally dependable FL500 flame detector conducts its own self-check every two minutes. These optical and electrical self-check diagnostic routines ensure the sensor’s optical path is clear and that the detector’s sophisticated electronic circuitry is operational for true operator peace-of-mind.

The FL500 detector also can be tested with the explosion proof TL105 Test Lamp, which simulates the flickering of a fire and provides a high-energy, broadband radiation source that emits energy in both the ultraviolet and infrared spectra to safely activate the flame sensors. The TL105 Test Lamp allows the detector to be tested under real fire conditions without the associated risk of an open flame.

With its compact design, the FL500 UV/IR flame detector offers a reduced footprint and simplified wiring to make it easy-to-install and maintain. The detector’s rugged 316 stainless steel housing measures a compact 4.5-inches (114 mm) in diameter by 5.5-inches (140 mm) in length and weighs only 9 pounds (4.0 kg).

Designed for fire safety monitoring in the most demanding environments, the FL500 Detector features comprehensive safety approvals for use around the globe--from the heat of the Middle East to the frigid regions of Northern Europe and Canada. The operating temperature range is: -67°F (-55°C) to 185°F (85°C) with a relative humidity range of 0 to 95% RH, non-condensing.

Beyond its FM performance approval, other global approvals include: CSA, ATEX, IECEx, EN 54-10 and CE Marking. The proven FL500 UV/IR Flame Detector represents the true future of flame monitoring performance, reliability, flexibility and value.